Slip casting is the process of filling the molds with slip which is the liquid clay allowing it to solidify and after a while forming a layer called the cast inside of the mold s walls.

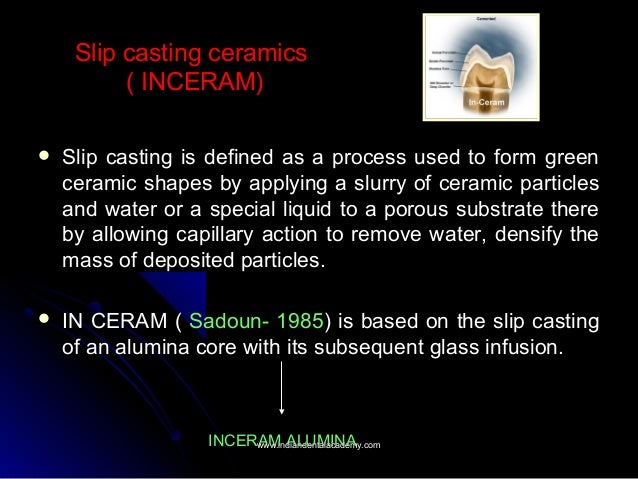

Slip casting of ceramics definition.

Slip casting definition a pottery making process in which partially liquefied clay is poured into a plaster mold.

The process usually takes at least 24 hours per piece.

As mentioned above with sufficient water content and the addition of suitable dispersing agents clay water mixtures can be made into suspensions called.

A different approach to the forming of clay based ceramics is taken in slip casting of whiteware as shown in figure 1.

Slip casting in general is a process developed for high speed low skilled factory production.

In other words slip casting usually means new or reproduction or at the very least modern.

Before the wide spread use of slip casting most ceramic and pottery items were almost totally made by hand.